Products

Phage Display and Recombinant Antibody Services

Recombinant antibodies, unlike the traditional hybridoma antibodies, its unique advantages in customization, high-throughput production and large-scale antibody production. Due to their low lot-to-lot variability and high specificity, recombinant antibodies are being touted as the future of antibodies in research. This means the diverse set applications utilizing antibodies such as immunodiagnostics and other biologics-based analytical research can benefit greatly from recombinant antibodies. iReal Biotechnology provides a flexible, one-stop solution for recombinant antibody development needs.

The phage display is also a technology for the generation of high quality candidates for human and veterinary therapeutic applications.

- Immune library from immunized animals or donors

- High throughput screening system

- Recombinant antibody production (several formats available)

Lower antibody yield

Highly training & experienced technician

What are Recombinant Antibodies?

- Fv, variable fragment

- scFv, single chain Fv in which light and heavy chain fragments

- (scFv)2, fragment that consists of two scFv molecules connected by a disulfide bond

- dsFv, variable fragment stabilized by additional intramolecular disulfide bond

- Fab- and (Fab)2, fragments

- VH, heavy chain variable domain

- A Single domain antibody (sdAb)

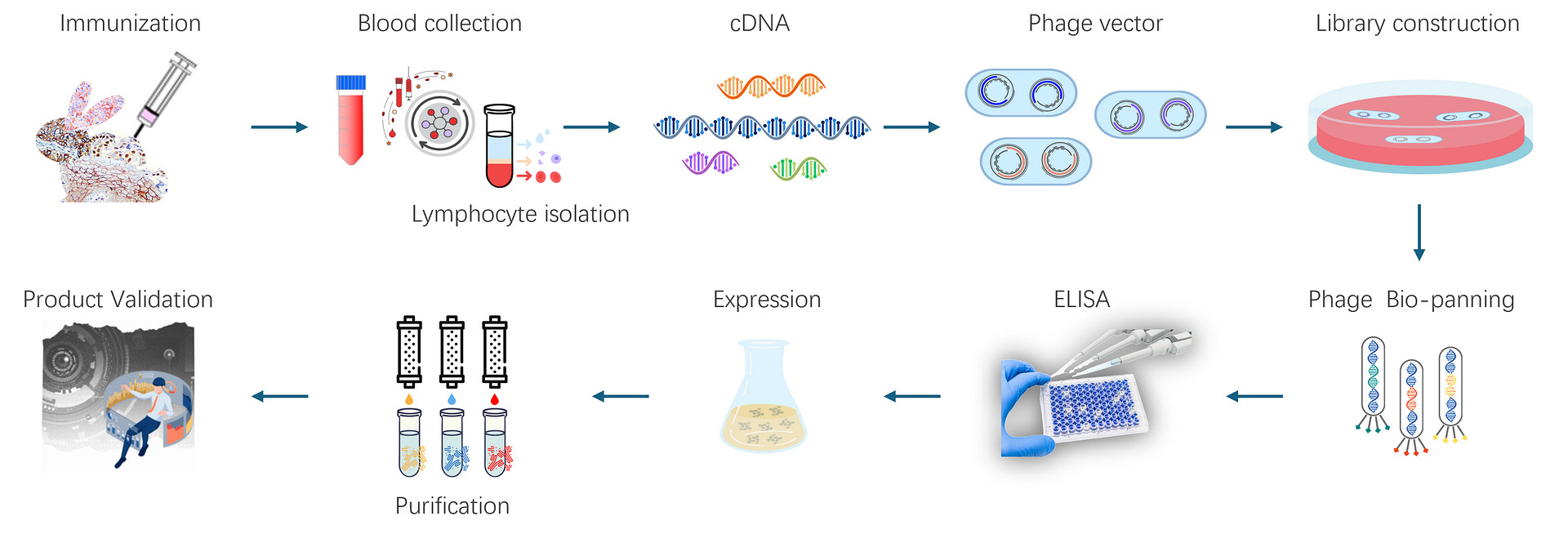

Rabbit Recombinant Monoclonal Antibody Workflow

The small size (15 kDa) and high stability of VHH antibody make it a promising tool for disease diagnosis and treatment. For example thanks to their small size (15 kDa), VHH can be transported more easily through certain physiological barriers. Additionally, VHH antibody expresses well in many host systems, making it cost-effective for large-scale manufacturing

| Advantages |

|||

| •Small Size |

|||

| •Superior Stability |

|||

| •Low Immunogenicity |

|||

| •High Affinity and Specificity |

|||

| •Versatile Production |

|||

| •Easy Conjugation |

|||

| •Robustness in Bioengineering |

VHH Antibody |

Mab |

|

| |

Size |

12 - 15 kD |

Approximately 150 kD |

| Required Antigen Amount |

≦1.5 mg |

≦5 mg |

|

| Method |

Camelid VHH library screening |

Hybridoma technology |

|

| Stability |

High stability to heat, pH and denaturing agents |

Thermal instability |

|

| Lot-to-Lot Consistency |

Very high |

High |

|

| Lead Time |

8-24 weeks |

16-24 weeks |

|

| Process |

Output / Product and QC |

Time course |

||

| Project specificaions |

The target of interest |

membrane protein, small molecule, post-translation modifications, etc. |

||

| Therapeutic / Diagnosis Applications |

||||

| Specifications |

Available material, specificity, deadlines, etc. |

|||

| 1st stage Antigen design& preparation |

Protein Immunization |

Produce 2mg protein for immunization |

SDS-PAGE, Purity, Yield |

3-4 weeks |

| Peptide Immunization |

Synthesis 5mg protein for immunization |

CoA, HPLC-MASS |

||

| 2nd stage Animal immunization |

Standard immunization service : 2 Rabbit Within 5 times immunization 1 Alpaca Within 5 times immunization |

Rabbit : Dot titer Alpaca : ELISA titer |

8-12 weeks |

|

| 3rd stage scFv/VHH library & phage display |

scFv/VHH Phage Library Generation: Prediction of library size and positive percentage |

PBMC/Lymphocyte Collection RNA extraction cDNA synthesis/preparation Phage vector Library construction |

Colony counting and sequencing |

3-4 weeks |

| 4th stage Bio-panning and screening |

3-5 rounds of bio-panning |

Clone isolation Validation : ELISA、DNA sequencing |

1. Specific 1-5 clone sequences and DNA 2. VHH/scFv antibody 0.5 mL without purification 3. Phage validation through phage ELISA data |

3-4 weeks |

| Phage binding assay on ELISA |

||||

| Individual clone binding assay on ELISA |

||||

| Sequence analysis |

||||

| 5th stage: Antibody expression & purification |

Expression and purification |

Transformation into E.coli and expression SDS-PAGE result |

0.5 mg-1.0 mg/Ab |

2-3 weeks |

| ELISA titration |

Titration in duplicate at least |

10 serial dilution results |

||